CNC Panel Bender

CNC Panel Bender

Product advantages

Advanced CNC system, convenient operation experience

Equipped with a full-touch HMI and powerful CNC system, it offers intuitive operation, simplifying program input and parameter adjustment. This reduces operator learning costs and boosts efficiency. With Chinese-English menu switching and 3D graphic programming, it meets diverse user needs for smarter, more user-friendly operation.

Reliable clamping and positioning, excellent adaptability

Equipped with a mechanical servo clamping device, it ensures stable, strong clamping to prevent sheet metal displacement. Combined with a flexible positioning system, it accurately adapts to various shapes and sizes, reducing positioning errors and enhancing processing accuracy and adaptability.

Simple aesthetic appearance, practical and beautiful at the same time

The minimalist design features smooth lines and clean shapes, enhancing the workshop’s image while ensuring easy cleaning and maintenance. Its well-planned structure also supports internal components, extending equipment lifespan.

Green energy-saving pioneer, low consumption and silent operation

Designed for energy efficiency and environmental protection, it consumes less power than traditional equipment, cutting production costs. Its low noise operation improves the workshop environment, protects workers’ health, and supports green, sustainable industrial development.

Product Display

Core Technology

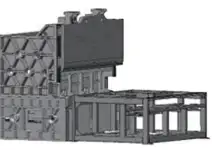

Machine Bed

It is made of high-specification castings, and both the cast and welded parts are subjected to strict stress relief processing. High-precision machine tools are used for integrated processing, ensuring long-term accuracy, stability, and high rigidity during operation.

Nitrogen Balancing System

No need for power system, saving energy; suitable for high-speed movement of machine tools Improves machining efficiency and extends the life of the screw by up to 10 times.

Separate Air-Conditioning

Strong heat dissipation for more stable machine performance.

Separate Vacuum Pump

Strong adsorption, higher precision, suitable for long time high temperature and high pressure operation.

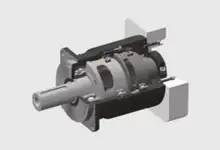

High-End Reducer

Small friction, high transmission efficiency, IP65 protection level, 90 degrees can also be continuous operation; stronger tensile rigidity, higher torsional rigidity,low noise high precision.

Servo Motor

Nut drive, higher precision, greater stability, higher efficiency, machining speed up to 200mm / S, repeat positioning accuracy t 0.01mm.

Technical Parameter

Suction Pad Type

| Item | Unit | MAC-100 | MAC-130 | MAC-150 |

| Bending length | mm | 1000 | 1300 | 1500 |

| Sheet length | mm | 1100 | 1400 | 1600 |

| Sheet width | mm | 1000 | 1250 | 1250 |

| Bending height | mm | 170 | 170 | 170 |

| Minimum formed internal dimensions on all four sides | mm | 350×150 | 350×150 | 350×150 |

| Double-sided minimum formed internal dimensions | mm | 150 | 150 | 150 |

| Minimum radius of circle | mm | 1.2 | 1.2 | 1.2 |

| Fastest continuous bending speed | s | 0.5/Kneif | 0.5/Kneif | 0.5/Kneif |

| Distance between upper and lower tool | mm | 180 | 180 | 180 |

| Bending angle | ° | 0-360° | 0-360° | 0-360° |

| Maximum material thickness | mm | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 |

| CNC control system | SMAC Star 300 | SMAC Star 300 | SMAC Star 300 | |

| Operating systems | OS | Win7+OS | Win7+OS | Win7+OS |

| Number of axes | axes | 8 axis as standard | 11axis as standard | 11axis as standard |

| Machine Dimensions (L×W×H) | mm | 3160×1440×2870 | 3370×1710×2650 | 3370×1900×2740 |

| Machine Weight | kg | 6000 | 8000 | 8500 |

| Total power | kw | 23.95 | 25.9 | 31.3 |

Lever Type

| Item | Unit | MAP-100 | MAP-130 | MAP-150 | MAP-200 | MAP-250 |

| Bending length | mm | 1000 | 1300 | 1500 | 2000 | 2500 |

| Sheet length | mm | 1100 | 1400 | 1600 | 2100 | 2600 |

| Sheet width | mm | 1250 | 1250 | 1250 | 1250 | 1250 |

| Bending height | mm | 170 | 170 | 250 | 170 | 175 |

| Minimum formed internal dimensions on all four sides | mm | 360×180 | 360×180 | 360×180 | 360×180 | 360×180 |

| Double-sided minimum formed internal dimensions | mm | 180 | 180 | 180 | 180 | 180 |

| Minimum radius of circle | mm | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Fastest continuous bending speed | s | 0.5/Kneif | 0.5/Kneif | 0.5/Kneif | 0.5/Kneif | 0.5/Kneif |

| Distance between upper and lower tool | mm | 180 | 180 | 180 | 180 | 180 |

| Bending angle | ° | 0-360° | 0-360° | 0-360° | 0-360° | 0-360° |

| Maximum material thickness | mm | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 | Aluminum plate: 2.0 Carbon steel: 1.5 Stainless steel: 1.2 |

| CNC control system | SMAC Star 300 | SMAC Star 300 | SMAC Star 300 | SMAC Star 300 | SMAC Star 300 | |

| Operating systems | OS | Win7+OS | Win7+OS | Win7+OS | Win7+OS | Win7+OS |

| Number of axes | axes | 9 axis as standard | 12 axis as standard 14 axis as optional | 12 axis as standard 14 axis as optional | 13axis as standard 14 axis as optional | 11 axis as standard |

| Machine Dimensions (L×W×H) | mm | 4015×1440×2900 | 3650×2300×2650 | 4050×1900×2780 | 4580×2400×2950 | 5080×2890×2950 |

| Machine Weight | kg | 7500 | 9000 | 9500 | 13800 | 18000 |

| Total power | kw | 23.75 | 27.65 | 31.05 | 44.65 | 47 |