CNC Electric Servo Press Brake PB5-4015

CNC Electric Servo Press Brake PB5-4015

Product advantages

High-Efficiency Bending

Driven by a seryo motor with high response speed the processing efficiency is more than 1.5 times higher than that of traditional hydraulic press brakes. The ram approach speed reaches up to 30 mm/s, approximnately twice that of conventional electro-hydraulic press brakes.

Stable Precision

Bending speed can be adjusted according to different workpieces, utilizing optimal algorithms and motion trajectory control to enhance bending accuracy. Compared to traditional all-electric servo press brakes, this system eliminates belts and gear reducers, The seryo motor directly drives the ball screw, ensuring bending angle deviations within +0.5°, offering more stable precision.

Eco-Friendly and Energy-Saving

Consumes approximately 70% less energy than traditional electro-hydraulic press brakes. No hydraulic oil is required, making the system both energy-efficient and environmentally friendly.

User-Friendly and ow Maintenance

The drive system is simple, with no consumable sealing parts and no risk of oil eakage. Only periodic lubrication is needed, reducing maintenance costs. The operating system is easy to use, making operation more convenient and worry-free.

Rear Gear Positioning Bearings (15 Years Without Deformation)

The standard CNC backgauge is equipped with six axes: X, R, Y1, Y2, Z1, and Z2.The X-axis controls the overall horizontal (front-to-back) movement of the backgaugefingers.The R-axis controls the vertical (up-and-down) movement of the backgauge fingers, significantly improving operational efficiency and reducing labor intensity by making height adjustments easier.The Y1 and Y2 axes control the vertical movement of the upper beam.The Z1 and Z2 axes control the independent horizontal (left-to-right) positioning of the two backgauge fingers.This six-axis configuration demonstrates outstanding efficiency and flexibility, especially for applications requiring frequent changes in sheet width or angled bending.

Servo Motor

With ball screw drive ensures higher precision., greater stability, and improved efficiency. It achieves processing speeds of up to 200mm/s, with a repeat positioning accuracy of ‡0.01mm.

Ball Screw and Linear Guideways

Featuring high-precision ball screws manufactured by HIWIN, this system offers enhanced positioning accuracy. Combined with a fully equipped backgauge, it ensures faster and more efficient bending operations.

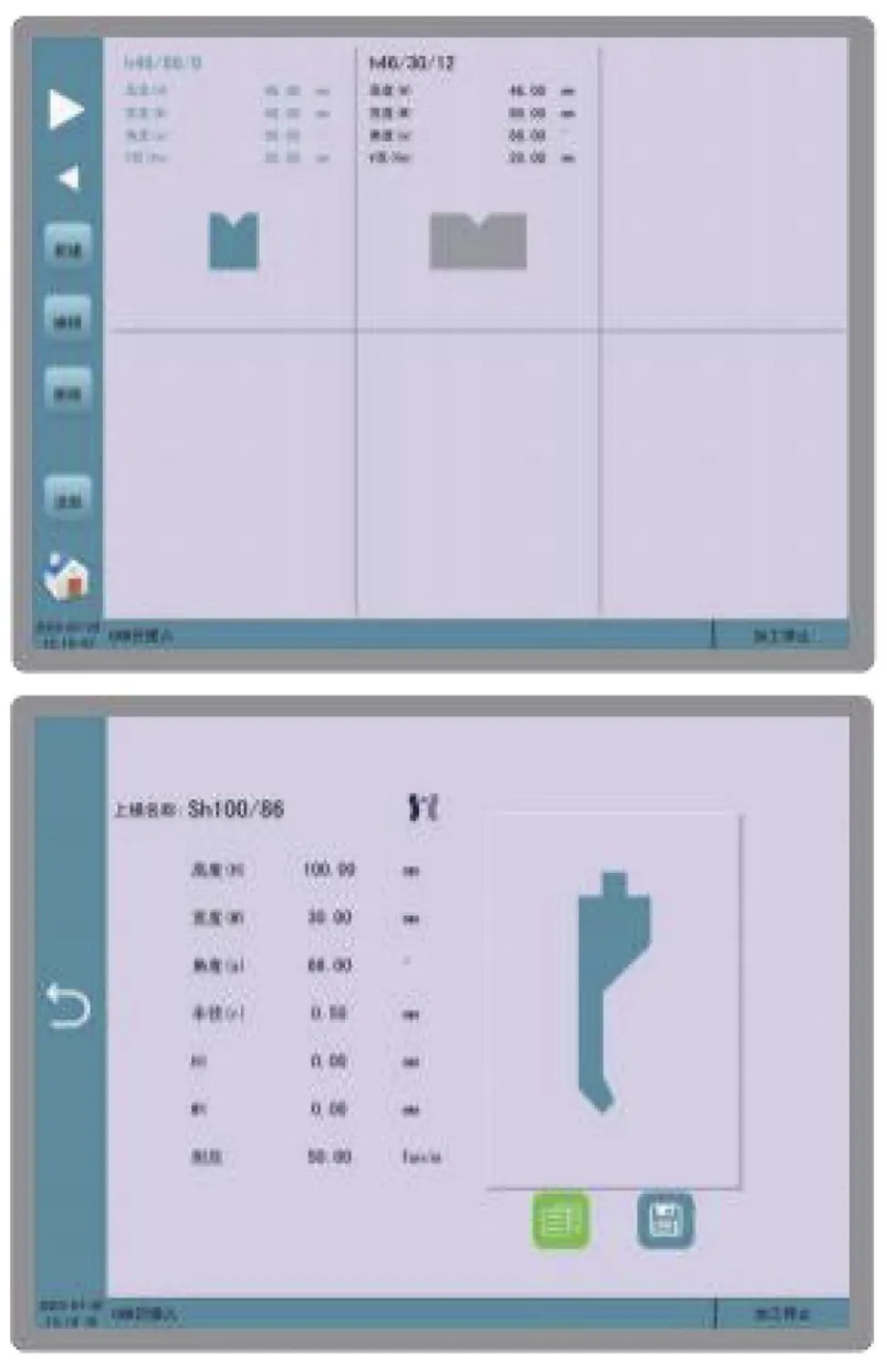

Digital Bending System

• Self-developed height system

• 15-inch TFT high-definition touch screen

• Handcrankwheel control, easy to operate, 2 hours to learn

• Intelligent alarm, rapid elimination, simple maintenance

• 2D graphic display and automatic bending;

• Plug access to the U disk, easy to save, restore product information,adjust the parameters of the machine

• Emergency stop button, the machine stops all movements in case of emergenc

Technical Parameter

| Item | Unit | PBS-3512 | PBS-4015 | PBS-6020 | PBS-8025 | PBS-10032 |

| Nominal Pressure | Ton | 35 | 40 | 60 | 80 | 100 |

| Table Length | mm | 1200 | 1500 | 2000 | 2500 | 3200 |

| Column Spacing | mm | 1130 | 1430 | 1930 | 2190 | 2870 |

| Table Height | mm | 855 | 855 | 855 | 855 | 855 |

| Opening Height | mm | 420 | 420 | 420 | 420 | 500 |

| Throat Depth | mm | 400 | 400 | 400 | 400 | 400 |

| Upper Table Stroke | mm | 150 | 150 | 150 | 150 | 200 |

| Upper Table Rise/Fall Speed | mm/s | 200 | 200 | 200 | 200 | 180 |

| Bending Speed | mm/s | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

| Back Gauge Front/Rear Travel Range | mm | 500 | 500 | 500 | 500 | 600 |

| Back Gauge Front/Rear Travel Speed | mm/s | 250 | 250 | 250 | 250 | 250 |

| Back Gauge Lift/Elevate Travel Range | mm | 150 | 150 | 150 | 150 | 150 |

| Back Gauge Lift/Elevate Travel Speed | mm/s | 130 | 130 | 130 | 130 | 130 |

| Number of machine axes | axis | 6 | 6 | 6 | 6+1 | 6+1 |

| Total power capacity | KVA | 20.75 | 29.5 | 34.5 | 52 | 60 |

| Main motor power | KW | 7.5*2 | 11*2 | 15*2 | 20*2 | 22*2 |

| Machine weight | Kg | 3000 | 3500 | 5000 | 7200 | 8200 |

| Machine dimensions | mm | 1910x1510x2270 | 2210x1510x2270 | 2720x1510x2400 | 3230x1510x2500 | 3060x1850x2600 |

| Total power | Kw | 16.6 | 23.6 | 31.6 | 41.6 | 46.6 |