CNC Servo Press Series

High Precision Strong Steel Frame Press

APS Servo Press Series

Features: 15~315tons

- With high rigidity design in machine frame, themachine body is welded of quality steel sheet and treated by tension elimination, improve stability and reliability of precision of the machine.

- Keep the transmission center and machine center inuniformity, guarantee the precision of pressing.

- In order to guarantee the machine running in stableand smooth, adopts the design of symmetrical boards with balancer.

- The precision of mold adjusting up to1mm, safety, reliable and convenient.

- After crank, gear, connect bar are hardening-oxidized and milled, they have super comprehensive mechanical performance and durable function.

- With reliable high sensitive clutch/brake and international up-to-date twin electromagnetic valve, and overloading protector, servo press machine can guarantee the precision of slider running and stop and safe production of the machine.

- With reasonable structural design, it is beneficialto fufill automation production and reduce cost ,improve efficiency.

- Advanced design principle, low noise, low consumption, low cost , save energy

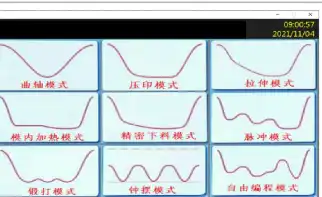

CNC Features

– CNC Servo control system: -Siemens 57-200 PLC+ 10″ HMl+ CPU; – Driver: BySTORM Italy— EMS: BySTORM Italy;- Encode: Tamagawa Japan ;- Servo motor : Delta

– With high rigidity design in machine frame,the machine body is welded of quality steel sheet and treated by tension elimination, improve stability and reliability of precision of the machine.

– Keep the transmission center and machine center in uniformity, guarantee the precision of pressing.

– In order to guarantee the machine running in stable and smooth, adopts the design of symmetrical boards with balancer.

– The precision of mold adjusting up to 0.1mm,safety,reliable and convenient.

– Crank, gear.connect bar are oxidized hardening and milled, having super comprehensive mechanical performance and durable function.

– CNC servo control Reasonable structural design, is benefit for automation production and reduce cost, improve efficiency.

– Advanced design principle, low noise, low consumption, low cost, save energy.

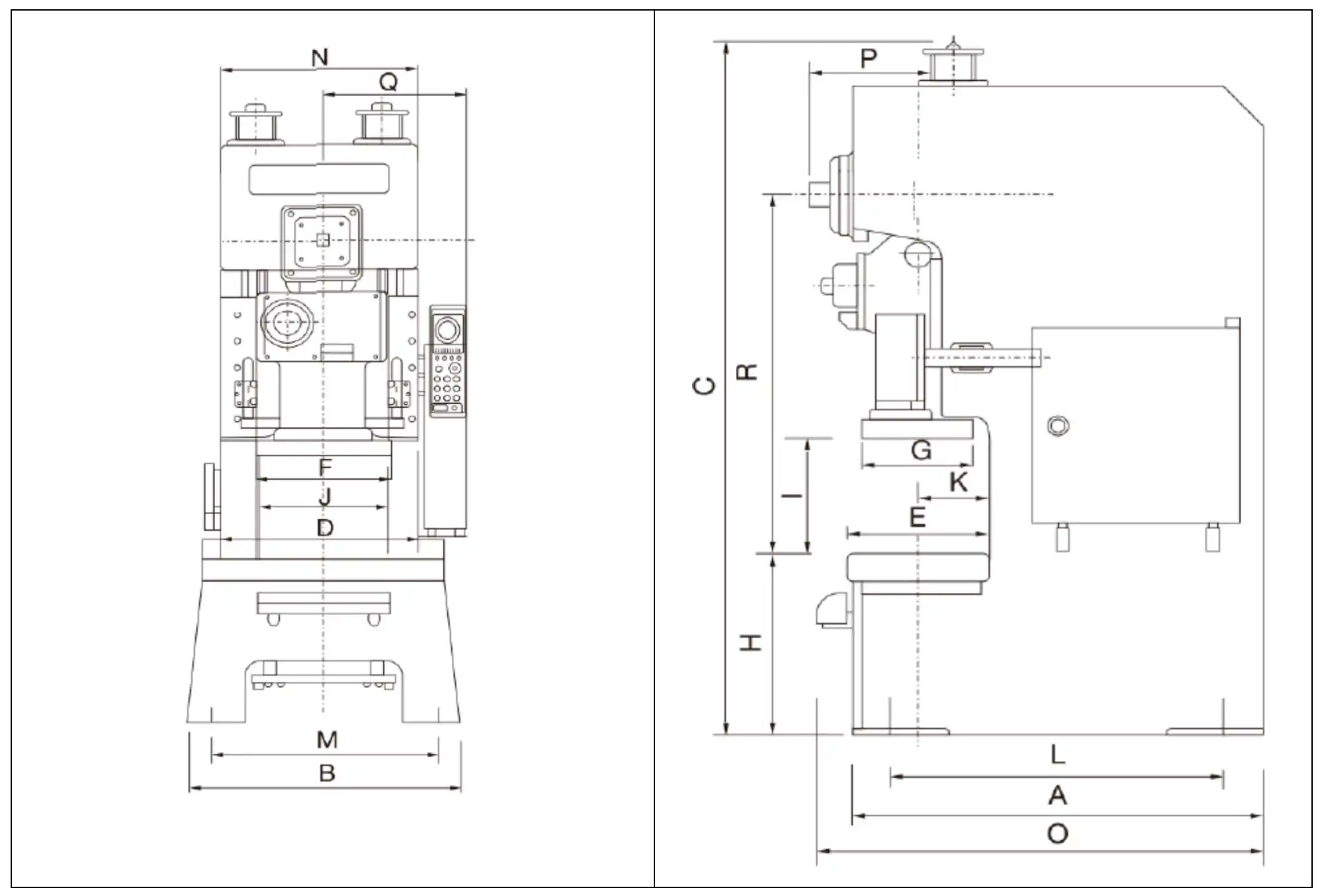

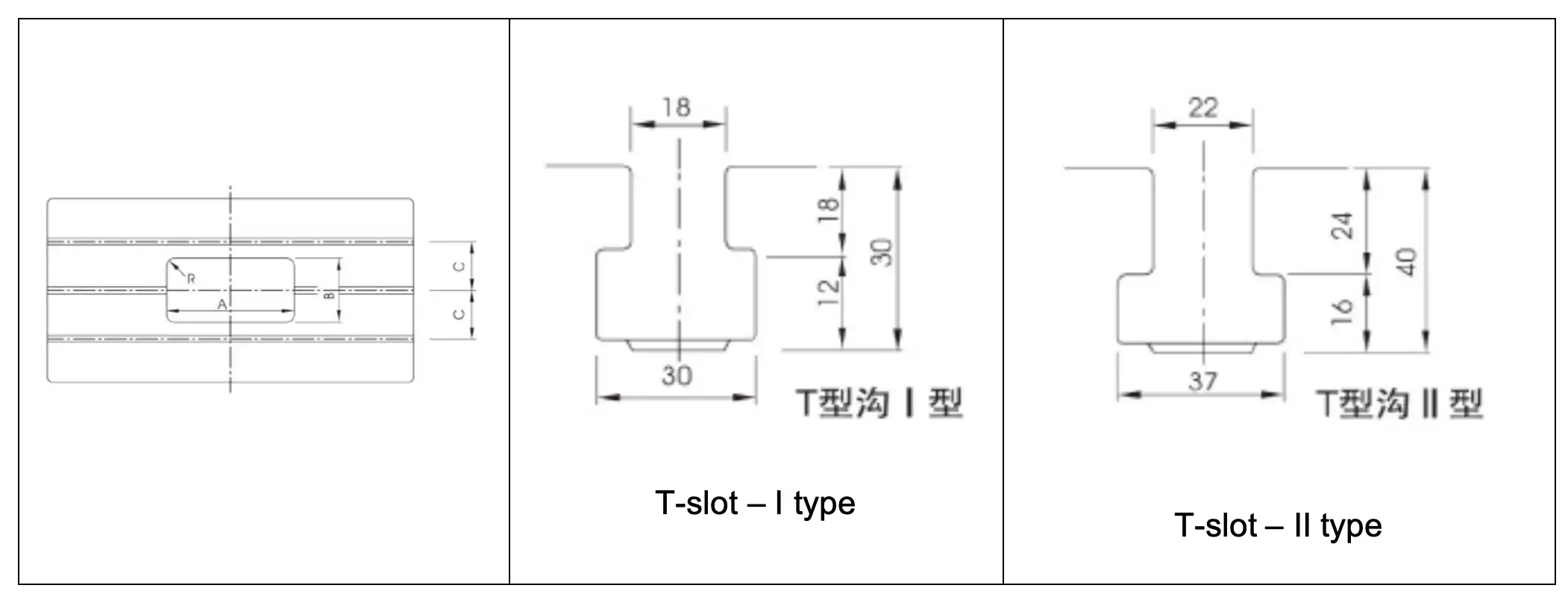

Overall Machine Dimension

| Pecification | APS-25 | APS-35 | APS-45 | APS-60 | APS-80 | APS-110 | APS-160 | APS-200 | APS-260 | APS-315 |

| A | 1100 | 1200 | 1400 | 1420 | 1595 | 1720 | 2140 | 2440 | 2605 | 2605 |

| B | 840 | 900 | 950 | 1000 | 1170 | 1290 | 1390 | 1690 | 1850 | 1870 |

| C | 2135 | 2345 | 2425 | 2780 | 2980 | 3195 | 3670 | 4075 | 4470 | 4490 |

| D | 680 | 800 | 850 | 900 | 1000 | 1150 | 1250 | 1400 | 1500 | 1500 |

| E | 300 | 400 | 440 | 500 | 550 | 600 | 800 | 820 | 840 | 840 |

| F | 470 | 520 | 560 | 700 | 770 | 910 | 990 | 1130 | 1130 | 1130 |

| G | 250 | 285 | 340 | 400 | 420 | 470 | 550 | 630 | 700 | 700 |

| H | 800 | 790 | 800 | 795 | 830 | 830 | 910 | 1030 | 1030 | 1030 |

| I | 260 | 290 | 320 | 420 | 480 | 530 | 650 | 650 | 750 | 750 |

| J | 444 | 488 | 502 | 526 | 534 | 616 | 660 | 790 | 900 | 900 |

| K | 160 | 205 | 225 | 255 | 280 | 305 | 405 | 415 | 430 | 430 |

| L | 980 | 1040 | 1170 | 1180 | 1310 | 1420 | 1760 | 2040 | 2005 | 2005 |

| M | 700 | 800 | 840 | 890 | 980 | 1100 | 1200 | 1400 | 1560 | 1580 |

| N | 540 | 620 | 670 | 720 | 780 | 920 | 1000 | 1160 | 1300 | 1320 |

| O | 1275 | 1375 | 1575 | 1595 | 1770 | 1895 | 2315 | 2615 | 2780 | 2780 |

| P | 278 | 278 | 313 | 333 | 448 | 488 | 545 | 593 | 688 | 688 |

| Q | 447 | 560 | 585 | 610 | 620 | 685 | 725 | 805 | 875 | 885 |

| R | 935 | 1073 | 1130 | 1378 | 1506 | 1650 | 1960 | 2188 | 2460 | 2480 |

Standard accessories/optional configuration

| No. | Configuration name | Picture for reference |

| 01. | Coolant system of servo motor |  |

| 02. | Overload pump pressure gauge, Clutch pressure gauge, Balancer pressure gauge |  |

| 03. | Air pressure switch |  |

| 04. | Human control system (Display controller) |  |

| 05. | Wiring box |  |

| 06. | Joystick |  |

| 07. | Filter |  |

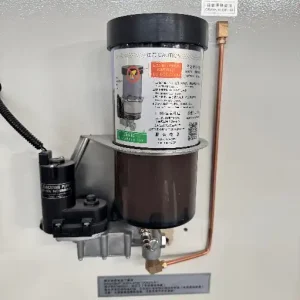

| 08. | Balancer electric oiler |  |

| 09. | Electric grease lubrication device |  |

| 010. | Dry clutch (in yellow) |  |

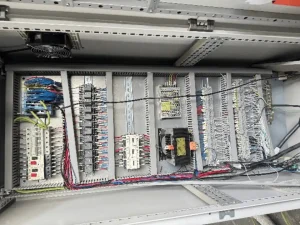

| 011. | Electrical control cabinet |  |

| 012. | Servo motor drive |  |

| 013. | CE protection |  |

| 014. | Photoelectric protection device |  |

| 015. | Anti-vibration feet |  |

| 016. | Manual greaser/oil pump |  |

Standard accessories

| No. | Standard accessories | Picture for reference/Brand/ note |

| 1 | Servo motor | Xinchuang (Fisher) servo motor |

| 2. | Control system | Simens |

| 3 | Hydraulic over-load protector |  |

| 4 | Manual ram adjustment device (60 tons and below) | |

| 5 | Electric ram adjustment device (80 tons and above) |  |

| 6 | Mechanical mold height indicator (60 tons and below) | |

| 7 | Electric mold height indicator (60 tons and above) |  |

| 8 | Ram and mold balancing device |  |

| 9 | Rotary cam switch |  |

| 10 | Misfeed detection device | In the human-computer counter system |

| Power socket | ||

| 11 | Crank angle indicator | In the human-computer counter system |

| 12 | Electrical stroke counter | In the human-computer counter system |

| 13 | Air source (air supply fitting) |  |

| 14 | Against over-run safety device | Equipped in the servo system |

| 15 | Air ejector (Air blow device) |  |

| 16 | Maintenance tool box |  |

| 17 | Direct-drive Permanent Magnet Synchronous Torque Motor |

|

| 18 | Operation manual |

Technical data sheet

| 名称 | Item name | Unit | APS-110 | ||

| 型号 | Model | V | H | ||

| 吨数 | Capacity | Ton | 110 | ||

| 冲力发生位置 | Rated tonnage point | mm | 6 | 3 | |

| 每分钟行程数 | 变速 | Variable speed | s.p.m. | 30-60 | 60-90 |

| 定速 | Stable speed | mm | 50 | ||

| 行程 | Stroke | mm | 180 | 80 | |

| 最大闭合工作高度 | Max. Die Set height | mm | 360 | 410 | |

| 滑块调整量 | Slide adjustment | mm | 80 | ||

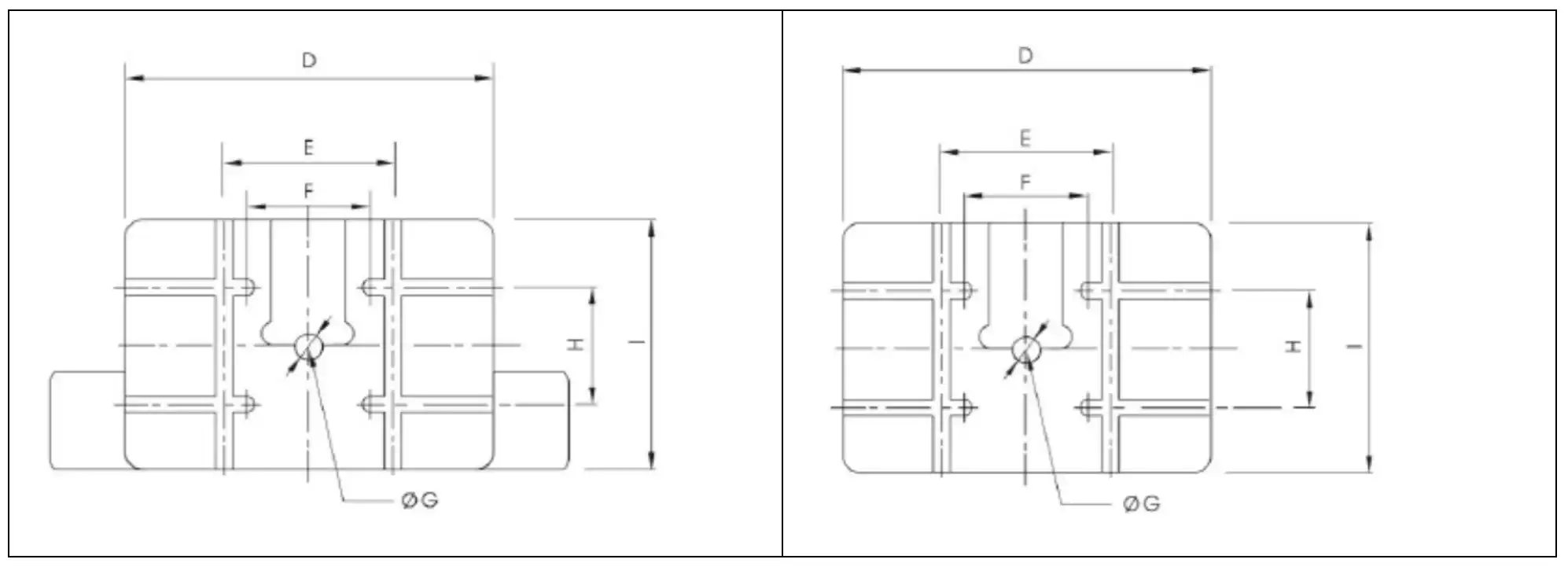

| 上工作台尺寸 | Upper workbench size | mm | 650x470x80 | ||

| 下工作台尺寸 | Lower workbench size | mm | 1150x600x110 | ||

| 模柄孔 | Mold Shank hole | mm | Φ50 | ||

| 主电动机 | Main motor | Kw.p | 11×4 | ||

| 滑块调整机构 | Slide adjust device | HP | Electrical driving | ||

| 使用空气压力 | Air pressure | Kg/cm2 | 6 | ||

| 冲床精度 | Press precision | mm | GB(JIS) 1class | ||

| 冲床(长x宽x高) | Overall machine dimension | Mm | 1900x1300x3200 | ||

| 冲床重量 | Machine weight | Ton | 9.6 | ||

| 模垫能力 | Die cushion capacity | Ton | 6.3 | ||

| 模垫行程长 | Die cushion stroke | Mm | 80 | ||

| 模垫有效面积 | Die cushion effective area | Mm2 | 500×350 | ||

Slide: Upper workbench

Working ability curve

Working ability curve

Note: All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.

Brand: Delta

Brand: Delta